Solutions

Locations

STAY CONNECTED

Signup for our blog to receive tips and knowledge on industrial wash and wash water treatment best practices.

WORK WITH US

Don’t settle for less than a solution from a partner who takes complete responsibility from start to finish. We make it easy to keep things clean and compliance effortless. Contact us today to discuss your wash water recycling and industrial wash needs.

The Evans Bio System (EBS) is the premier solution for industrial wash water treatment in a closed loop system. Using a proven bioremediation process, the EBS rapidly breaks down organic contaminants such as oil, grease, diesel, drilling mud. The microbes then convert these into water and carbon dioxide, resulting in reusable water for your wash bay or pressure washer, or cleaner, compliant discharge.

Engineered in marine-grade aluminum, the EBS delivers durability, ease of installation, and reliable performance in the toughest industrial environments.

How It Works

Wastewater treatment systems are highly specific – a unit designed for suspended solids may not efficiently remove emulsified oils or heavy metals, and vice versa.

The Evans Bio System applies a biological treatment process that uses naturally occurring microbes to break down light ot medium contamination, including:

- Grease

- Oils

- Drilling mud

- Hydrocarbons

- Organic matter

This process effectively and rapidly degrades organic contaminants, producing clean water (100-50 microns) suitable for reuse or compliant discharge.

Treatment Process:

- Collection & Containment: Contaminated wash water enters the EBS unit.

- Biological Breakdown: Microbes digest oils, greases, and hydrocarbons, then convert them into water and CO₂.

- Separation & Polishing: Remaining solids settle out, leaving clear, treated water ready for reuse or compliant discharge.

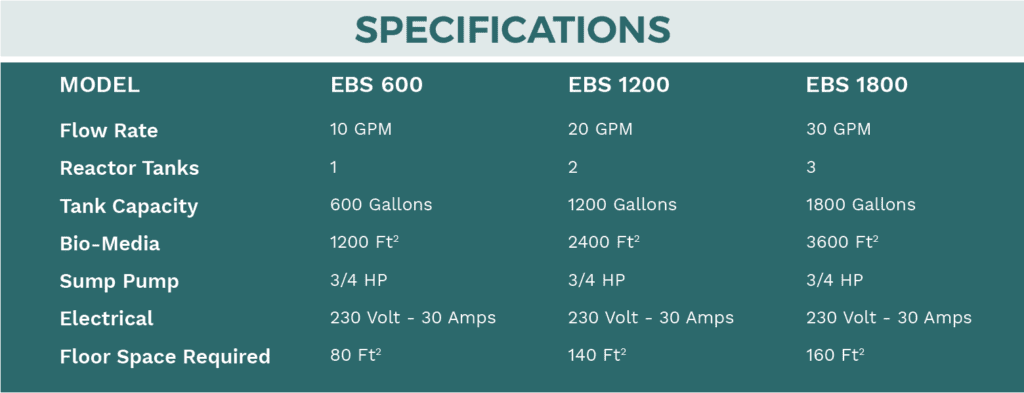

Specifications & Key Features

- Marine-grade aluminum construction for corrosion resistance and longevity

- Easy installation — self-contained and skid-mounted with forklift pockets

- Rapid biodegradation of oil, grease, diesel, and hydrocarbons

- Compact footprint for mobile or fixed-site use

- Available in multiple capacities based on flow rate and site requirements.

Wherever there’s heavy equipment and oily wash water, the EBS turns your environmental challenge into a closed-loop solution.

Ideal For: Demanding operations that generate oily, hydrocarbon-heavy wash water.

- Oil & Gas

- Military

- Government

- Power Generation

- Heavy Equipment

- Construction

- Transportation

- Municipalities

Compatibility & Systems Integration

For sites facing both organic and suspended solid contamination, the EBS can be paired with an Evans Mechanical Filtration System (EMF) or Oil Water Separator for a customized wash water treatment solution.

- Oil Separator: removes heavy oils and solids before biological treatment

- Evans Mechanical Filtration System (EMF): filters out clays, silts, and flocs

- Evaporator or Recycle System: manage water reuse or disposal efficiently

Together, these systems create a closed-loop wash bay setup that minimizes environmental impact and ensures regulatory compliance.

1. What contaminants can the Evans Bio System remove?

The EBS is designed to break down organic contaminants such as oil, grease, diesel, drilling mud, and hydrocarbons.

2. How clean is the treated water?

The EBS can reduce contamination down to approximately 100–50 microns. For finer filtration, pair with an Evans Mechanical Filtration System.

3. Is microbial activity tracked in the EBS?

The best indicator of microbial activity is your water quality. When the system is functioning properly, you’ll see clear, consistent results. If water quality starts to decline, that’s a sign the microbes have gone anaerobic (meaning they’ve stopped working and gone dormant). To prevent that, the EBS is designed to keep microbes healthy and active by continuously circulating and oxygenating the water. The flow from the sump maintains just enough movement to keep the microbes thriving — because they don’t like to sit still.

4. Is this system easy to install?

Absolutely. Each unit is skid-mounted and self-contained, making setup fast and straightforward.

5. Does it require ongoing maintenance?

Like all wash water systems and equipment, the EBS benefits from scheduled maintenance to monitor biological activity and keep the system running efficiently. Evans offers scheduled maintenance programs nationwide.

6. Does it meet EPA discharge standards?

Yes. The EBS helps your facility stay compliant with EPA and local discharge regulations by treating wastewater before discharge or reuse.

7. Is this system customizable?

Yes, it can be combined with other Evans wash water recycling systems to support wastewater solids management.

8. What maintenance is required?

Regular maintenance includes removing solids, checking and cleaning filters, and ensuring that the chemical coagulate and microbe levels are satisfactory. Due to evaporation, the system may require water to be added on occasion. Ideally, the water should be hauled off approximately once a year. Schedule Evans Maintenance to enroll in expert technician protection.